A research team led by Professor Xiaoshi Qian from the SJTU School of Mechanical Engineering has designed and synthesized a new lead-free perovskite oxide featuring a high-polar-entropy state that exhibits a giant electrocaloric effect. Their work sheds light on the fundamental relationship between atomic-scale structure and material performance.

On April 9, Professor Xiaoshi Qian’s group, in collaboration with Professor Shujun Zhang from Australia’s University of Wollongong, published a research article titled “Giant electrocaloric effect in high-polar-entropy perovskite oxides” in Nature. By deliberately disrupting the order of the polar structure at the atomic scale, the team developed a "high-polar-entropy ceramic" with lattice-level disorder. This innovation significantly enhanced the giant electrocaloric effect in lead-free ferroelectric ceramics. The study offers a new material design strategy for electrocaloric refrigeration technologies and demonstrates cross-scale fabrication of integrated multilayer electrocaloric refrigerants.

Ph.D. student Feihong Du and Associate Professor Tiannan Yang from the School of Mechanical Engineering are co–first authors, with Professor Xiaoshi Qian and Professor Shujun Zhang serving as the corresponding authors.

The electrocaloric (EC) effect refers to the reversible entropy change of a polar dielectric when an electric field is applied. Due to this electric-field-induced entropy change, dielectric materials release heat upon charging and absorb heat upon discharging. Analogous to the vapor–liquid phase transition of gaseous refrigerants driven by compressors in traditional cooling systems, EC cooling systems rely on electric field cycling to drive heat absorption and release in dielectric materials, completing the cooling cycle. This emerging solid-state cooling paradigm features zero greenhouse gas emissions, high energy efficiency, and ease of miniaturization, and is considered a disruptive pathway for transitioning from electrical to electronic cooling technologies. A major challenge in the field is to design high-performance, scalable solid-state dielectric refrigerants from the atomic level.

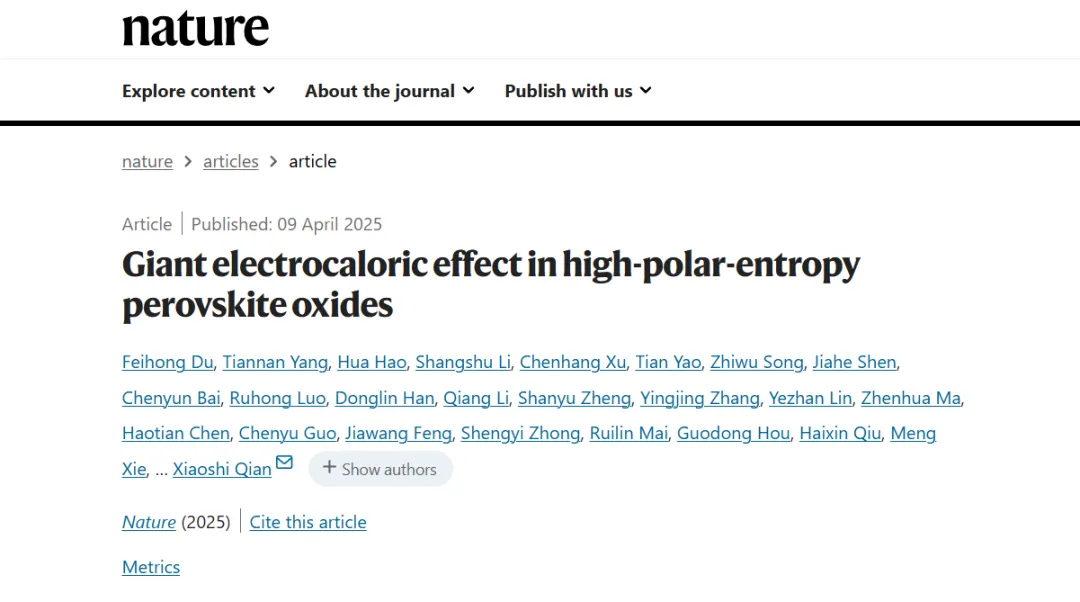

Figure 1. Design Strategy and Key Properties of High-Polar-Entropy Electrocaloric Ceramics

Ferroelectric ceramics, known for their high polarization strength, have long been studied as promising EC cooling materials. However, many high-performance EC ceramics contain large amounts of lead, scandium, and other elements, posing environmental and cost concerns for large-scale manufacturing. To address this, the research team focused on developing lead-free alternatives.

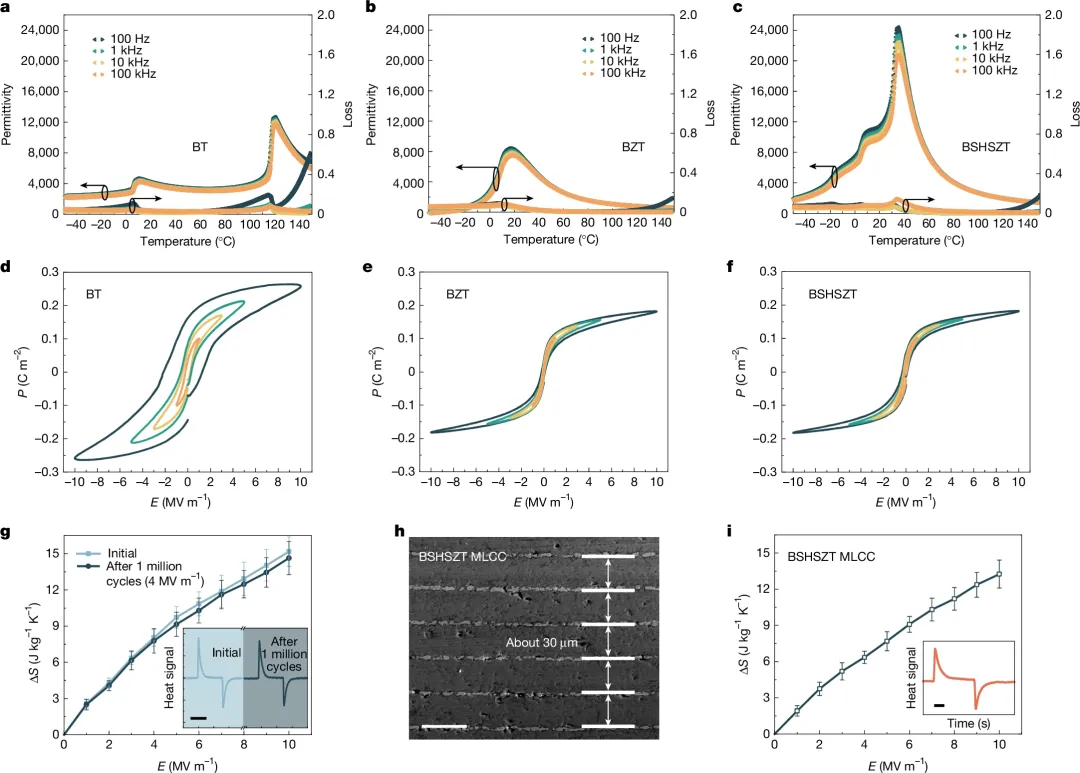

Building upon their previous Landau-phenomenological modeling of ferroelectric materials, the team proposed a novel inorganic oxide design approach featuring "high polar entropy." By strategically substituting multiple elements at both A and B sites in the ABO₃ perovskite structure of BaTiO₃-based ceramics, they synthesized a highly disordered lead-free relaxor ferroelectric: Ba₀.₈Sr₀.₂Hf₀.₀₂₅Sn₀.₀₂₅Zr₀.₀₂₅Ti₀.₉₂₅O₃ (BSHSZT). This configuration induced numerous interconvertible polar and nonpolar regions at the atomic scale. The existence of these polar nanodomains significantly increased domain wall density, thereby enhancing the material's polar entropy. Compared to structurally more ordered BaTiO₃ (BT) and BaZr₀.₂Ti₀.₈O₃ (BZT), BSHSZT exhibits a higher electrocaloric strength and a broader operating temperature range. Under a 10 MV·m⁻¹ electric field, the entropy change reaches approximately 15 J·kg⁻¹·K⁻¹—ten times that of BT—within a temperature window exceeding 60 °C near room temperature (Figure 1). This high-polar-entropy oxide features finely dispersed, multiphase lattice structures, high breakdown field strength, and stable cycling performance over one million cycles.

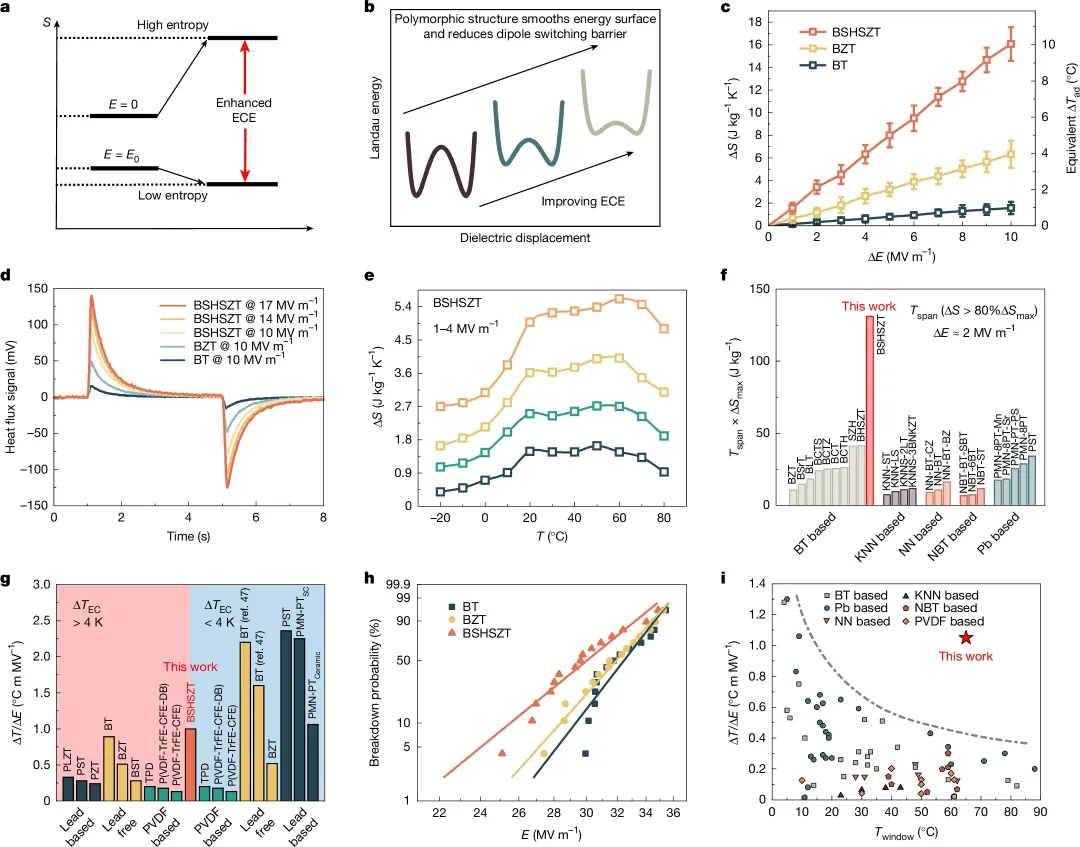

Figure 2. Nanoscale Polar Structure in High-Polar-Entropy EC Ceramics

Using transmission electron microscopy (TEM) and X-ray diffraction, the researchers revealed that BSHSZT possesses a significantly more disordered polar structure than BT and BZT. As the A-site and B-site substitutions increase structural perturbation, large ferroelectric domains in BT fragment into smaller, interlaced domains in BZT, and further evolve into tiny polar clusters in BSHSZT—each consisting of only a few unit cells. These clusters are much smaller than conventional polar nanoregions, and their polarization directions are randomly oriented. Phase-field simulations indicated that the interfaces between these clusters exhibit high responsiveness to electric fields, contributing substantially to polar entropy change and accounting for the large EC effect in BSHSZT (Figure 2).

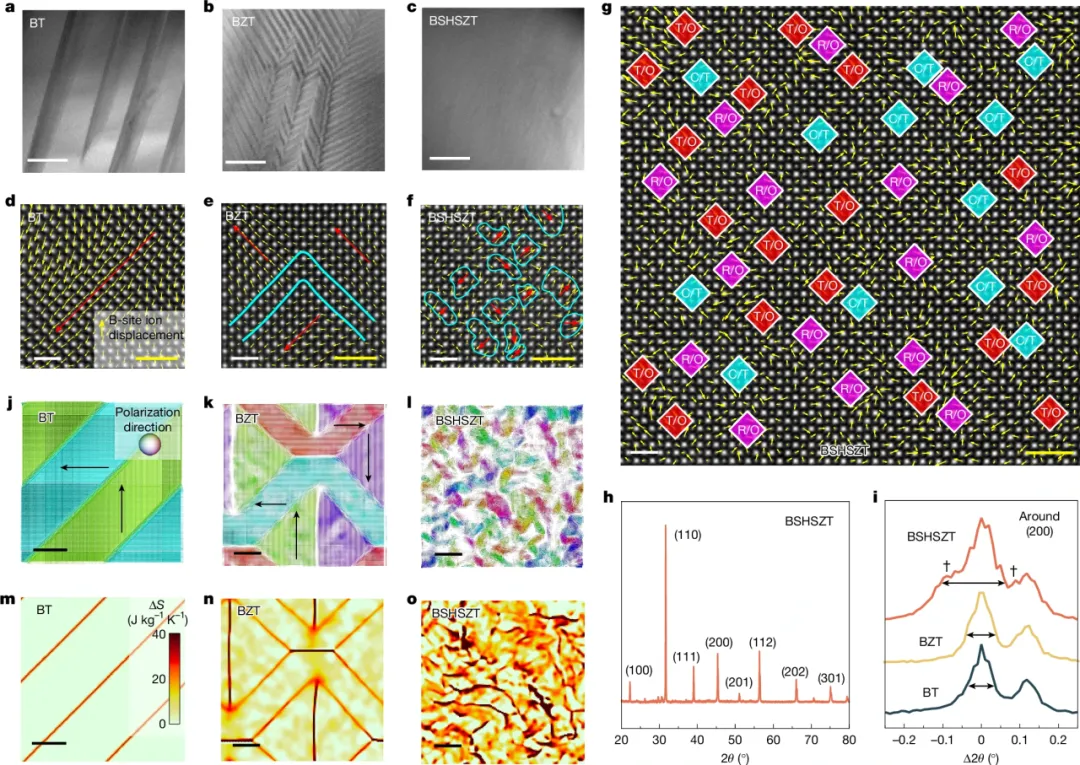

Figure 3. Polar Structure Evolution Under Electric Fields

The high-polar-entropy design strategy not only amplifies the electrocaloric entropy change but also lowers the energy barrier for electric-field-induced phase transitions. Under in situ electric field characterization, TEM images showed that disordered polar clusters in BSHSZT readily merge and reorient under applied fields. Compared with BT and BZT, BSHSZT exhibited greater decreases in both grazing-incidence small-angle X-ray scattering (GISAXS) and optical second-harmonic generation (SHG) signals before and after field application—evidence of reduced energy barriers for polarization switching (Figure 3).

Figure 4. Cross-Scale Fabrication of Multilayer EC Refrigerants

BSHSZT ceramics display a much higher dielectric constant than BT and BZT, confirming their elevated electric field tunability. Their polarization strength remains relatively unchanged at high fields, indicating that the enhanced EC effect originates from increased zero-field entropy, not from polarization strength at finite fields. Based on BSHSZT ceramics, the team fabricated multilayer ceramic capacitors, reducing the driving voltage and significantly increasing the cooling capacity of the material as an EC refrigerant. BSHSZT ceramics exhibit an EC strength 1000% greater than BT and 250% greater than BZT, with stable cycling performance exceeding one million cycles. Their EC effect remains robust and temperature-stable in the 15 °C to 75 °C range, making them suitable for practical cooling applications (Figure 4).

Acknowledgments

The research was supported by Associate Researcher Zhengqian Fu (Shanghai Institute of Ceramics, CAS), Professor Shengyi Zhong (School of Materials Science and Engineering, SJTU), Professor Dong Qian (School of Physics and Astronomy, SJTU), Associate Professor Yakun Yuan (Zhangjiang Institute for Advanced Study), and Professor Hua Hao (School of Materials Science and Engineering, Wuhan University of Technology). Professors Xiangyang Zhu, Guang Meng, Jiangping Chen, and Associate Professor Xin Chen from the School of Mechanical Engineering at SJTU provided important guidance. Professors Longqing Chen (Pennsylvania State University), Hanxing Liu (Wuhan University of Technology), Genshui Wang and Xuefeng Chen (Shanghai Institute of Ceramics, CAS), and Professor Dao Xiang (SJTU) offered valuable support to the project.

This research was funded by the Ministry of Science and Technology of China under the Key Research and Development Program for Transformational Technologies and Fundamental Scientific Questions, as well as by the National Natural Science Foundation of China, the Shanghai Natural Science Foundation, and SJTU programs including “SJTU 2030,” the “Siyuan Scholar” initiative, and the Key Frontier Research Fund. Experimental support was provided by the SJTU Center for Student Innovation, the SJTU Analytical & Testing Center, the National Major Science and Technology Infrastructure for Translational Medicine (Shanghai), and the BL16B1 beamline at the Shanghai Synchrotron Radiation Facility.